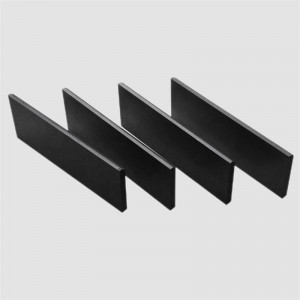

Vacuum Pump Graphite Carbon Vane

Features

We can specifically manufacture carbon graphite blades of various sizes for oil-free vacuum pumps and compressors. As components of pumps, carbon blades have strict requirements in terms of material properties, mechanical dimensions, and positional tolerances. The quality of carbon blades has been widely validated and recognized in long-term usage of vacuum pumps. We provide carbon blade matching services for many domestic water pump manufacturers, distributors, and users. We have already exported our pumps, components, and carbon blades to over 40 countries and regions.

Take measurements of the length, width, and thickness. However, if you are measuring old blades, the width may not be accurate as the blades wear down and become shorter. In that case, you can measure the depth of the rotor slot to determine the width of the blades.

Determine the number of blades needed per set: The number of rotor slots corresponds to the number of blades per set.

When using a new pump, pay attention to the direction of the motor and avoid connecting it to reverse gear. Prolonged reverse rotation of the pump will damage the blades.

Excessive dust in the pump's operating environment and inadequate air filtration can accelerate blade wear and reduce blade lifespan.

Moist environments can cause corrosion on the blades and the rotor slot walls. When starting the air pump, the blade components should not be thrown out, as uneven stress can damage the blades. In such cases, the blades should be inspected and cleaned first.

Frequent switching while using the pump increases the number of impacts during blade ejection, reducing the lifespan of the blades.

Poor blade quality can result in decreased pump performance or damage to the cylinder walls, so it should be avoided.

Carbon blades are consumable materials that wear out over time and can affect the performance of the air pump, eventually causing damage. When this happens, you will need to replace the blades. Here's how:

Before replacing the blades, use compressed air to clean the rotor slot, air pump cylinder walls, cooling pipes, and filter bladder.

Check for any wear or damage on the cylinder walls. If the blade material is too hard, it can cause damage to the cylinder walls. If the cylinder walls are damaged, the air pump may produce noise and the blades can become brittle.

When installing the new blades, make sure the tilt direction of the blades matches the curvature of the rotor slot (or the low and high points of the sliding width match the low and high points of the rotor slot depth). If the blades are installed upside down, they will get stuck and break.

After replacing the blades, first disconnect the air hose, start the air pump, and expel any remaining graphite fragments and dust from the air pump. Then, connect the hose and proceed to use it.