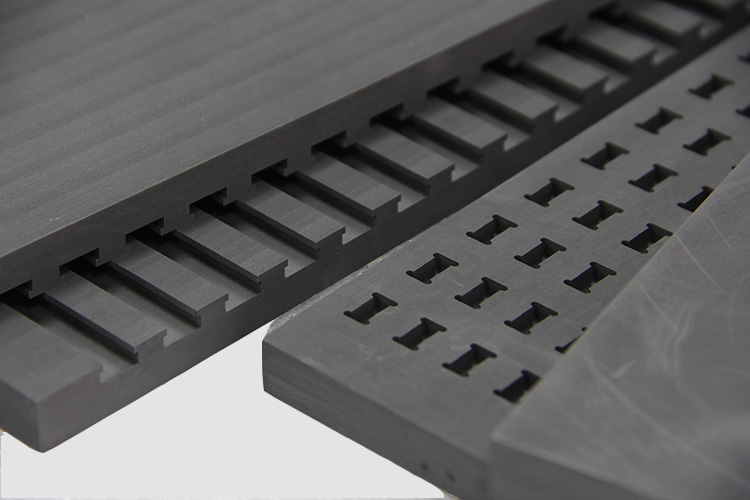

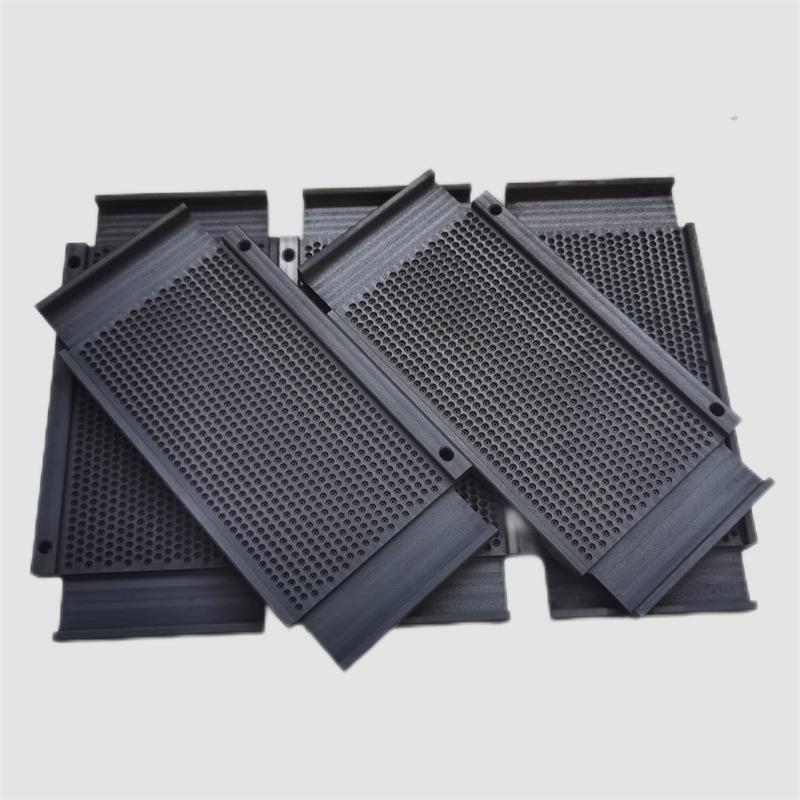

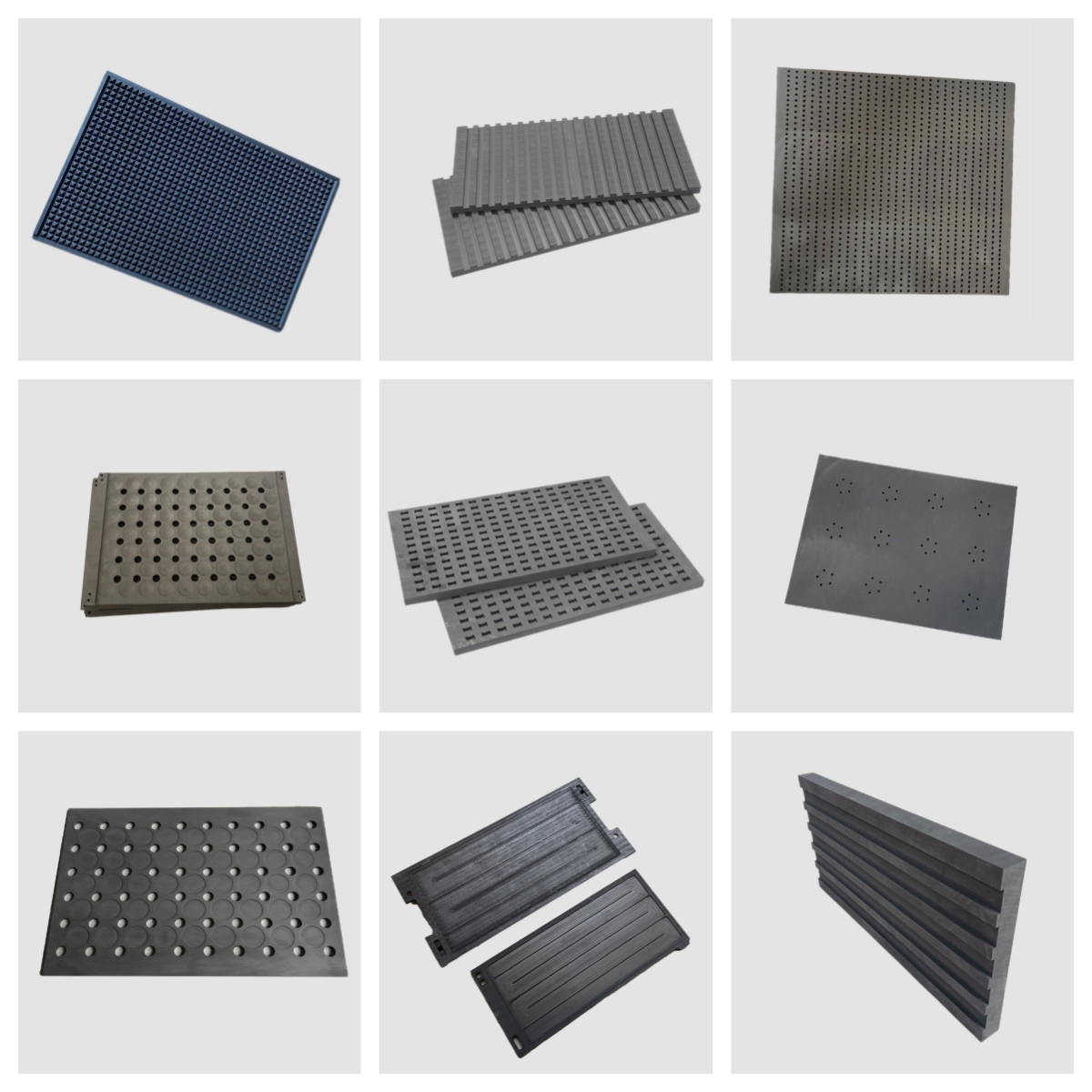

CNC customized graphite plate

Features

1) Refractory materials: In the smelting industry, graphite plates are used to manufacture graphite crucibles, as protective agents for steel ingots, and as magnesia carbon bricks for the lining of smelting furnaces.

2) Conductive materials: In the electrical industry, graphite is widely used as electrodes, brushes, carbon tubes, and coatings for television tubes.

3) Wear resistant materials and lubricants: In many mechanical equipment, graphite plates are used as wear resistant and lubricating materials, which can slide at a speed of 100m/s within the temperature range of -200 to 2000 ℃ without or with minimal use of lubricating oil.

4) Sealing material: Use flexible graphite as piston ring gaskets, sealing rings, etc. for centrifugal pumps, water turbines, steam turbines, and equipment transporting corrosive media.

5) Corrosion resistant material: Using graphite plates as vessels, pipelines, and equipment, it can withstand the corrosion of various corrosive gases and liquids and is widely used in departments such as petroleum, chemical, and hydrometallurgy.

6) Thermal insulation, high-temperature resistance, and radiation protection materials: Graphite plates can be used as neutron moderators in nuclear reactors, as well as nozzles, nose cones, aerospace equipment parts, thermal insulation materials, radiation protection materials, etc.

1. Good isotropy, characteristics independent of size, shape, and sampling direction;

2. Uniform structure, density, and strong antioxidant ability;

3. Excellent self-lubrication;

4. Good resistance to chemical corrosion;

5. High thermal conductivity and thermal stability performance;

6. Adequate mechanical strength and impact resistance;

7. Easy to machine and can be processed into various geometric shapes according to requirements.

When using a new pump, pay attention to the direction of the motor and avoid connecting it to reverse gear. Prolonged reverse rotation of the pump will damage the blades.

Excessive dust in the pump's operating environment and inadequate air filtration can accelerate blade wear and reduce blade lifespan.

Moist environments can cause corrosion on the blades and the rotor slot walls. When starting the air pump, the blade components should not be thrown out, as uneven stress can damage the blades. In such cases, the blades should be inspected and cleaned first.

Frequent switching while using the pump increases the number of impacts during blade ejection, reducing the lifespan of the blades.

Poor blade quality can result in decreased pump performance or damage to the cylinder walls, so it should be avoided.

1. Strong processing ability, able to provide different specifications and spliced graphite plates.

2. We can provide graphite products for extrusion molding, vibration molding, molding, and isostatic pressing molding as needed.

3. According to different technical requirements, graphite products such as graphite plates can be subjected to oxidation resistance treatment, impermeability treatment, and reinforcement treatment to improve their performance and service life.