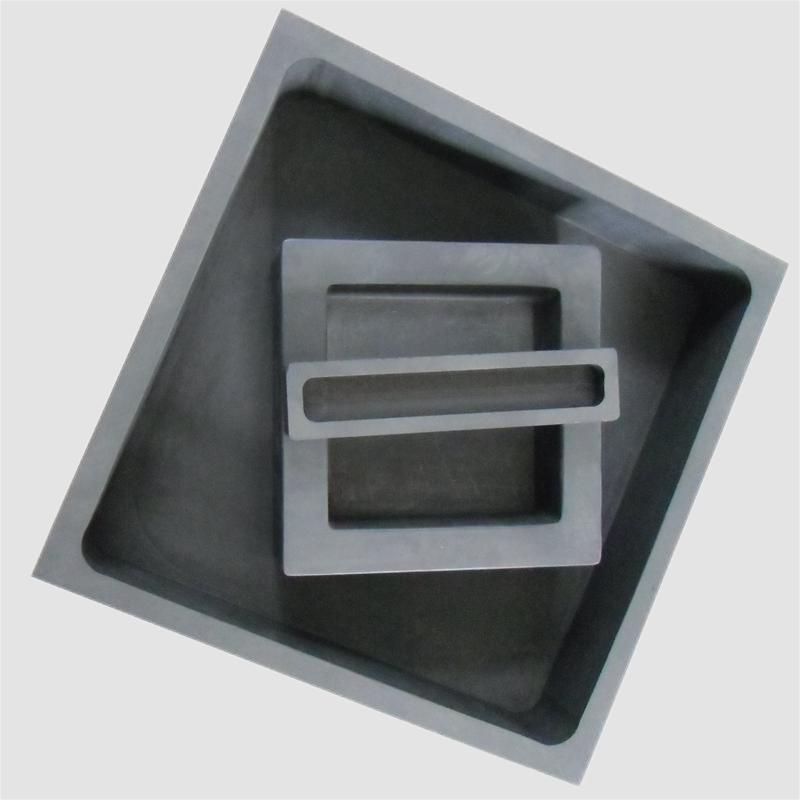

Graphite Sagger Anode For Battery

Features

The purpose of graphite armor bowl is to sinter powder materials (batteries, negative electrode materials, etc.). Generally, the material selection is mold pressing or isostatic pressing (priority). This product mainly serves as a sintering mold, so it is necessary to ensure the purity of the product. Due to the significant differences in the size, shape, and purpose of each mold, the customer first provides the original design drawings and fills out a complete questionnaire on the on-site use environment of the graphite mold. Then, based on the drawings and the usage environment of the graphite mold, a technical analysis is conducted to propose a suitable treatment plan.

Density: greater than 1.7

Carbon content: 99.9

Bending resistance: 35MPA

Compression resistance: 72MPA

Resistance: 14 Oufang

Thermal expansion coefficient: 3.6

Ash content: < 0.2%

1. High temperature resistance: Graphite is currently one of the most high-temperature resistant materials known. It has a melting point of 3850 ° C and a boiling point of 4250 ° C. It is subjected to an ultra-high temperature arc at 7000 ° C for 10 seconds, with the smallest loss of graphite, which is 0.8% by weight. From this, it can be seen that the high-temperature resistance of graphite is very outstanding.

2. Special thermal shock resistance: Graphite has good thermal shock resistance, that is, when the temperature suddenly changes, the coefficient of thermal expansion is small, thus it has good thermal stability, and will not produce cracks during sudden changes in temperature.

3. Thermal conductivity and conductivity: Graphite has good thermal conductivity and conductivity. Compared with ordinary materials, its thermal conductivity is quite high. It is 4 times higher than stainless steel, 2 times higher than carbon steel, and 100 times higher than ordinary non-metallic materials.

4. Lubricity: The lubrication performance of graphite is similar to that of disulfide, with a friction coefficient less than 0.1. Its lubrication performance varies with the size of the scale

The larger the scale, the smaller the friction coefficient, and the better the lubrication.

5. Chemical stability: Graphite has good chemical stability at room temperature, and can withstand acid, alkali, and organic solvent corrosion.

1. We always provide customers with high-quality products and the best solutions

Our brand has physical factories under direct sales! A professional main production and processing direct sales brand! Our material usage is authentic (without cutting corners), all for new material smelting. There are too many good secondary recycled processing materials on the market, and only with affordable prices can they be more sustainable and have better friend exhibitions. We need to create excellent raw material production brands, establish a reputation for raw material brands, and better serve everyone.

2. Can I have a sample?

Yes, you can communicate with our customer service and send you samples for free, but the postage will be borne by yourself

3. Is the quality good?

We guarantee the smelting of new materials and refuse the secondary recycling and processing of old materials. Please rest assured to purchase