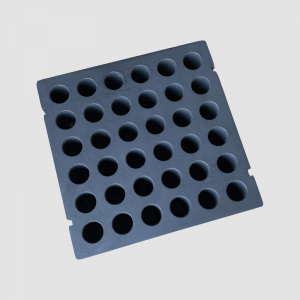

Custom Graphite Mold

Features

Our company specializes in carbon graphite products: seven major series:

1. Non ferrous metal smelting and processing series

2. Diamond tool sintering mold series

3. Mechanical Industry Series

4. EDM series

5. Industrial furnace high-temperature treatment series

6. Electronic Semiconductor Industry Series

7. High tech field series

- Precision manufacturing

- Precise processing

- Direct sales from manufacturers

- Large quantities in stock

- Customized according to drawings

The main products of production and operation include: various specifications of graphite blocks, graphite discs, large-sized graphite tube hard alloys, graphite Arks for powder metallurgy sintering, graphite circular boats, graphite semi circular boats, graphite shaped boats, push boat plates and graphite molds, crystallizers for continuous casting of non-ferrous metals, stoppers, bottom bowls, bases, pouring pipes, flow channel sheaths, chemical mechanical seals, high-purity graphite collapse, graphite rods, graphite plates, high wear-resistant graphite Die cast quartz glass produces graphite components such as bundle wheels, rollers, retaining walls, bottle clamps, etc. Graphite plates, graphite vessels, graphite heat exchangers, conductive rod graphite furnace bed plates, graphite bolts, nuts, graphite brackets, graphite molds required for vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitriding furnaces, and vacuum quenching furnaces for large saw smelting furnaces. Graphite furnace tubes and anti-corrosion plates for chemical purposes. Chlorine alkali industry, electroplating and electrolysis industry, graphite anode plate casting industry, graphite cold iron blocks for mold aluminum production, graphite rings, rollers, strips, plates, diamond tools, graphite molds, geological drill bit sintering molds for the production of new energy materials such as graphite cartridges for carp battery materials, graphite saggers, etc

All products are 100% physical photos, with first-hand supply and guaranteed quality. All displays, detailed dimensions, material labels, and product descriptions are provided with detailed instructions. If available on shelves, it means available. If you have any questions, please consult customer service promptly.

All products are photographed by professional photographers to ensure consistency with the actual product. However, due to the deviation in lighting, computer monitor resolution, and personal understanding of colors during shooting, the received item may differ from the image, which is not a quality issue. Please refer to the received item as the standard.