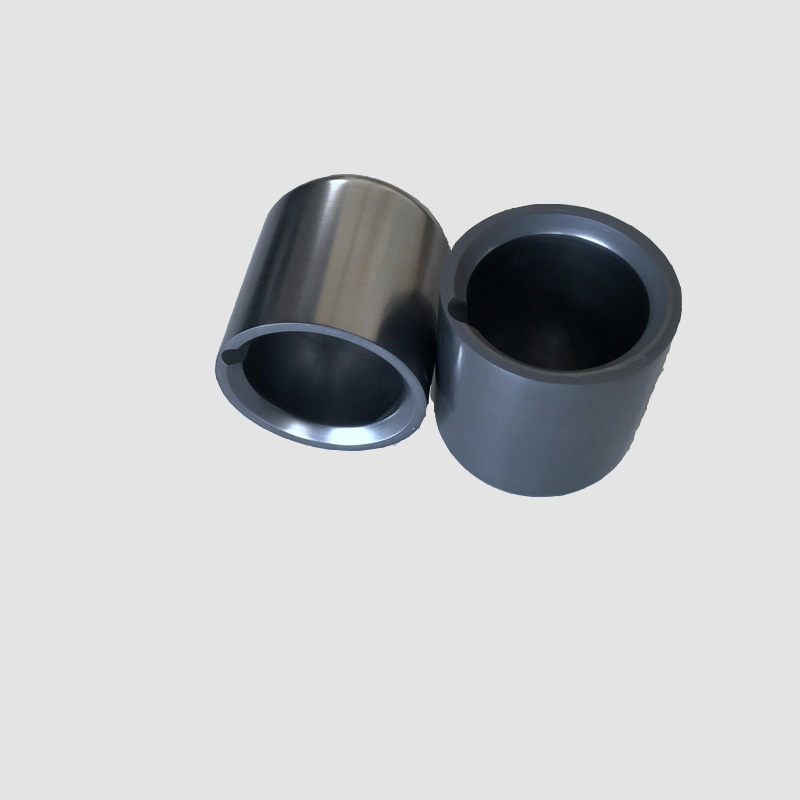

Graphite Crucible For Melting Gold

Features

Precious metal smelting is classified to primary smelting and refining. Refinery means getting high purity precious metal through smelting low purity metals, where graphite crucibles are needed with high purity, high bulk density, low porosity and good strength.

1. High temperature resistance, melting point 3850 ± 50 ° C, boiling point 4250.

2. Low ash content, high purity, to avoid contamination of your product.

3. Graphite is easy to process into any shape you like.

4. High mechanical strength

5. Good sliding performance

6. High thermal conductivity

7. High thermal shock resistance and chemical resistance

8. High corrosion resistance and oxidation resistance

9. Good conductivity

10. High density and high mechanical strength

11. The coefficient of thermal expansion is very small, and it has certain strain resistance for rapid cooling and heating.

12. Graphite crucibles have strong corrosion resistance and excellent chemical stability for acidic and alkaline solutions. Therefore, it does not participate in any chemical reactions during the smelting process.

13. The inner wall of the graphite crucible is smooth. The molten metal liquid is not easy to leak or adhere to the inner wall of the crucible, therefore it has good flowability and pouring ability.

| GRAPHITE&CERAMIC JEWELRY CRUCIBLE | ||||||

| Product Name | TYPE | φ1 | φ2 | φ3 | H | CAPACITY |

| 0.3kg Graphite Crucible | BFG-0.3 | 50 | 18-25 | 29 | 59 | 15ml |

| 0.3kg Quartz Sleeve | BFC-0.3 | 53 | 37 | 43 | 56 | ---------- |

| 0.7kg Graphite Crucible | BFG-0.7 | 60 | 25-35 | 35 | 65 | 35ml |

| 0.7kg Quartz Sleeve | BFC-0.7 | 67 | 47 | 49 | 63 | ---------- |

| 1kg Graphite Crucible | BFG-1 | 58 | 35 | 47 | 88 | 65ml |

| 1kg Quartz Sleeve | BFC-1 | 69 | 49 | 57 | 87 | ---------- |

| 2kg Graphite Crucible | BFG-2 | 65 | 44 | 58 | 110 | 135ml |

| 2kg Quartz Sleeve | BFC-2 | 81 | 60 | 70 | 110 | ---------- |

| 2.5kg Graphite Crucible | BFG-2.5 | 65 | 44 | 58 | 126 | 165ml |

| 2.5kg Quartz Sleeve | BFC-2.5 | 81 | 60 | 71 | 127.5 | ---------- |

| 3kgA Graphite Crucible | BFG-3A | 78 | 50 | 65.5 | 110 | 175ml |

| 3kg A Quartz Sleeve | BFC-3A | 90 | 68 | 80 | 110 | ---------- |

| 3kgB Graphite Crucible | BFG-3B | 85 | 60 | 75 | 105 | 240ml |

| 3kgB Quartz Sleeve | BFC-3B | 95 | 78 | 88 | 103 | ---------- |

| 4kg Graphite Crucible | BFG-4 | 85 | 60 | 75 | 130 | 300ml |

| 4kg Quartz Sleeve | BFC-4 | 98 | 79 | 89 | 135 | ---------- |

| 5kg Graphite Crucible | BFG-5 | 100 | 69 | 89 | 130 | 400ml |

| 5kg Quartz Sleeve | BFC-5 | 118 | 90 | 110 | 135 | ---------- |

| 5.5kg Graphite Crucible | BFG-5.5 | 105 | 70 | 89-90 | 150 | 500ml |

| 5.5kg Quartz Sleeve | BFC-5.5 | 121 | 95 | 100 | 155 | ---------- |

| 6kg Graphite Crucible | BFG-6 | 110 | 79 | 97 | 174 | 750ml |

| 6kg Quartz Sleeve | BFC-6 | 125 | 100 | 112 | 173 | ---------- |

| 8kg Graphite Crucible | BFG-8 | 120 | 90 | 110 | 185 | 1000ml |

| 8kg Quartz Sleeve | BFC-8 | 140 | 112 | 130 | 185 | ---------- |

| 12kg Graphite Crucible | BFG-12 | 150 | 96 | 132 | 210 | 1300ml |

| 12kg Quartz Sleeve | BFC-12 | 155 | 135 | 144 | 207 | ---------- |

| 16kg Graphite Crucible | BFG-16 | 160 | 106 | 142 | 215 | 1630ml |

| 16kg Quartz Sleeve | BFC-16 | 175 | 145 | 162 | 212 | ---------- |

| 25kg Graphite Crucible | BFG-25 | 180 | 120 | 160 | 235 | 2317ml |

| 25kg Quartz Sleeve | BFC-25 | 190 | 165 | 190 | 230 | ---------- |

| 30kg Graphite Crucible | BFG-30 | 220 | 190 | 220 | 260 | 6517ml |

| 30kg Quartz Sleeve | BFC-30 | 243 | 224 | 243 | 260 | ---------- |

1. Packed in plywood cases with 15mm min thickness

2. Each piece is separated by thickness foam to avoid touch and abrasion3. Tightly packed to avoid graphite parts moving during transportation.4. Custom packages are also acceptable.