Graphite is an allotrope of carbon, which is a gray black, opaque solid with stable chemical properties and corrosion resistance. It is not easily reactive with acids, alkalis, and other chemicals, and has advantages such as high temperature resistance, conductivity, lubrication, plasticity, and thermal shock resistance.

Therefore, it is commonly used for:

1.Refractory materials: Graphite and its products have properties of high temperature resistance and strength, and are mainly used in the metallurgical industry to manufacture graphite crucibles. In steelmaking, graphite is commonly used as a protective agent for steel ingots and as a lining for metallurgical furnaces.

2.Conductive material: used in the electrical industry to manufacture electrodes, brushes, carbon rods, carbon tubes, positive electrodes for mercury positive current transformers, graphite gaskets, telephone parts, coatings for television tubes, etc.

3.Graphite has good chemical stability, and after special processing, it has the characteristics of corrosion resistance, good thermal conductivity, and low permeability. It is widely used in the production of heat exchangers, reaction tanks, condensers, combustion towers, absorption towers, coolers, heaters, filters, and pump equipment. Widely used in industrial sectors such as petrochemical, hydrometallurgy, acid-base production, synthetic fibers, and papermaking.

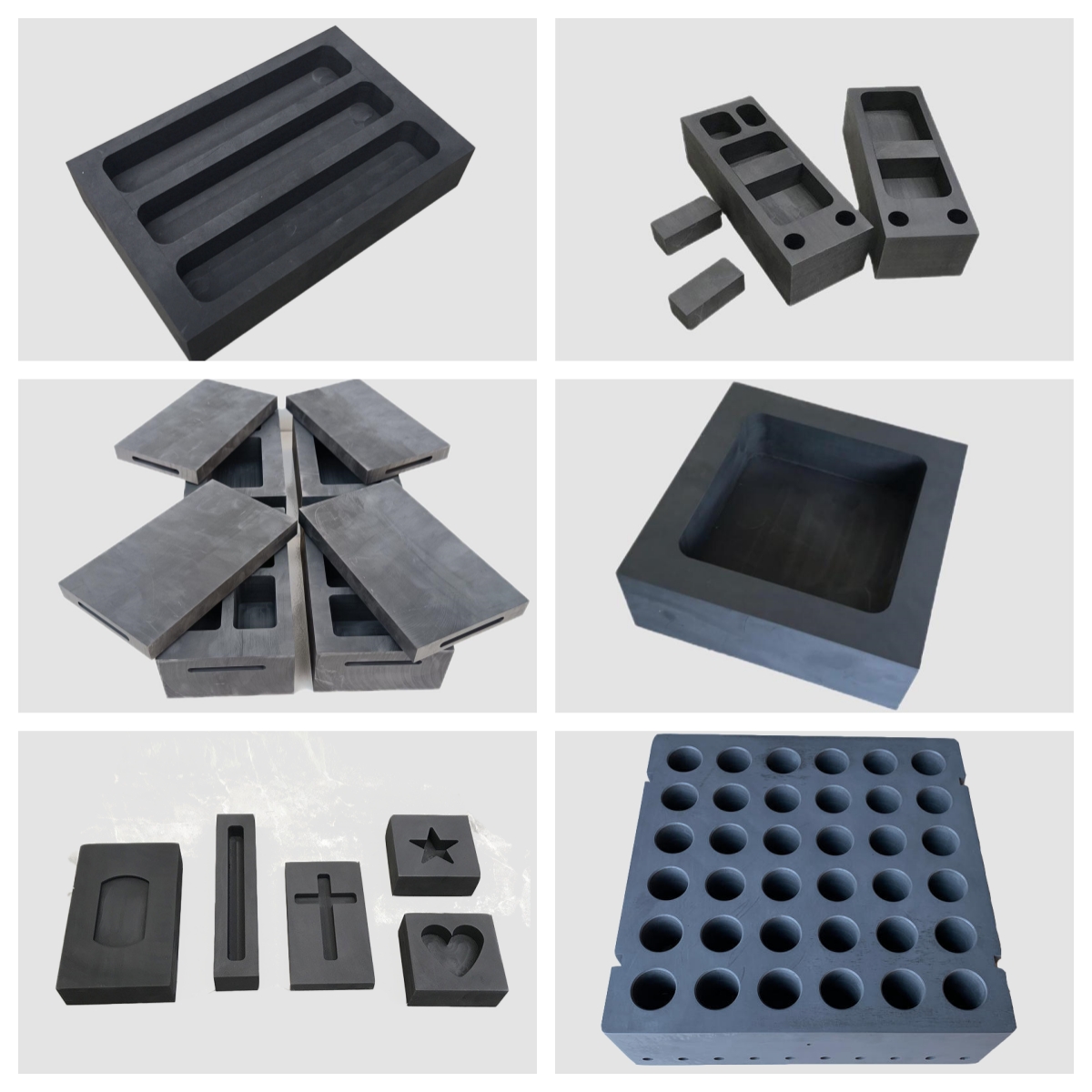

4.Making casting, sand turning, molding, and high-temperature metallurgical materials: Due to the small thermal expansion coefficient of graphite and its ability to withstand changes in rapid cooling and heating, it can be used as a mold for glassware. After using graphite, black metal can obtain precise casting dimensions, high surface smoothness, and high yield. It can be used without processing or slight processing, thus saving a large amount of metal.

5.The production of hard alloys and other powder metallurgy processes typically involves using graphite materials to make ceramic boats for pressing and sintering. The processing of crystal growth crucibles, regional refining containers, support fixtures, induction heaters, etc. for monocrystalline silicon cannot be separated from high-purity graphite. In addition, graphite can also be used as a graphite separator and base for vacuum smelting, as well as components such as high-temperature resistance furnace tubes, rods, plates, and grids.

Post time: Sep-21-2023