Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

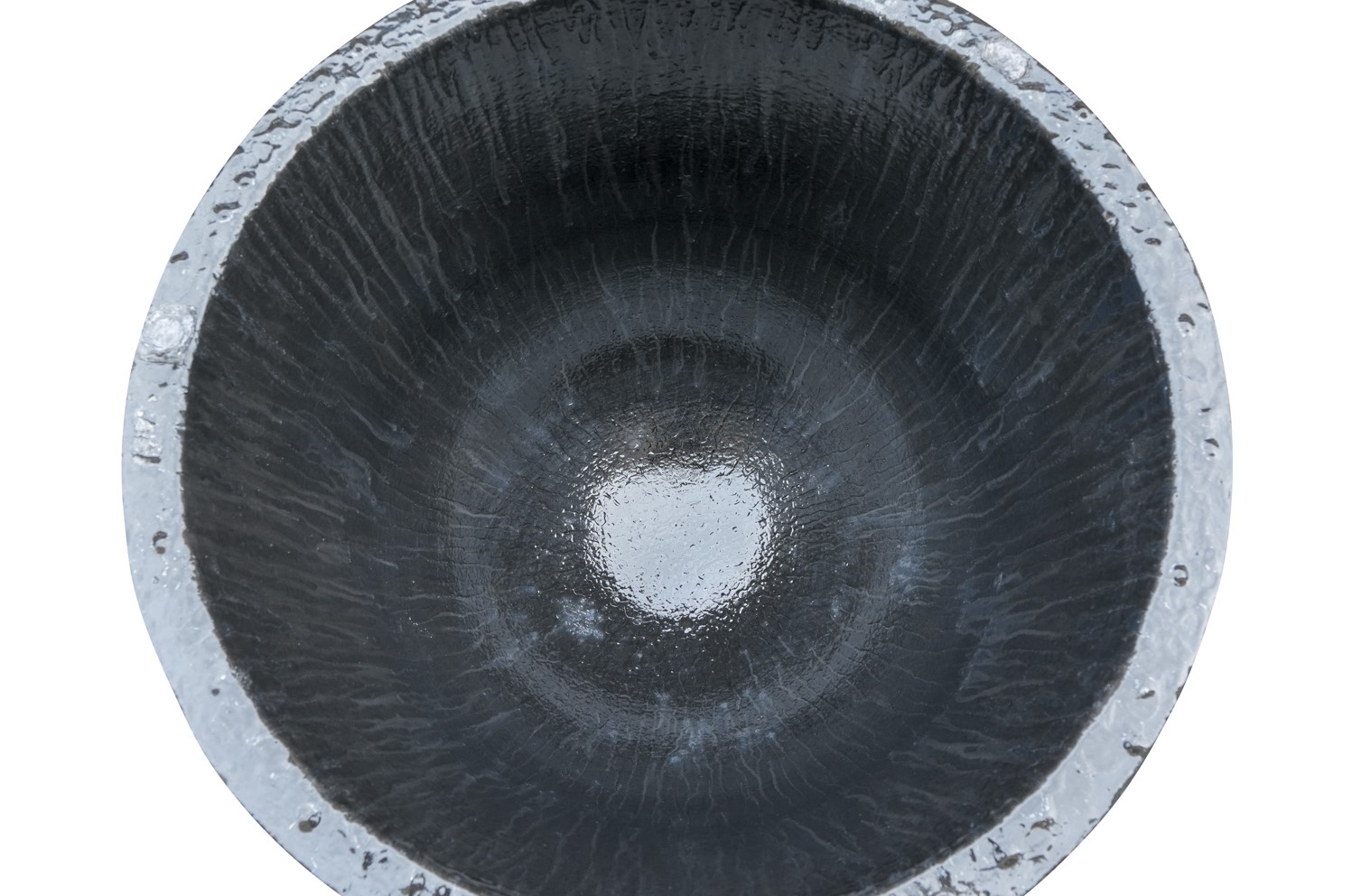

Crucible For Furnace For Metal Melting Foundry

PRODUCT FEATURES

Rapid Melting

High thermal conductivity graphite material improves thermal efficiency by 30%, significantly reducing melting time.

Superior Thermal Shock Resistance

Resin-bonded technology withstands rapid heating and cooling, allowing direct charging without cracking.

Exceptional Durability

High mechanical strength resists physical impact and chemical erosion for a longer service life.

TECHNICAL SPECIFICATIONS

| Graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Bulk density / g·cm⁻³ | 2.20 |

| Apparent porosity / % | 10.8 |

| Crushing strength/ MPa (25℃) | 28.4 |

| Modulus of rupture/ MPa (25℃) | 9.5 |

| Fire resistance temperature/ ℃ | >1680 |

| Thermal shock resistance / Times | 100 |

| No | Model | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

PROCESS FLOW

1. Precision Formulation

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

2.Isostatic Pressing

Density up to 2.2g/cm³ | Wall thickness tolerance ±0.3m

.

3.High-Temperature Sintering

SiC particle recrystallization forming 3D network structure

.

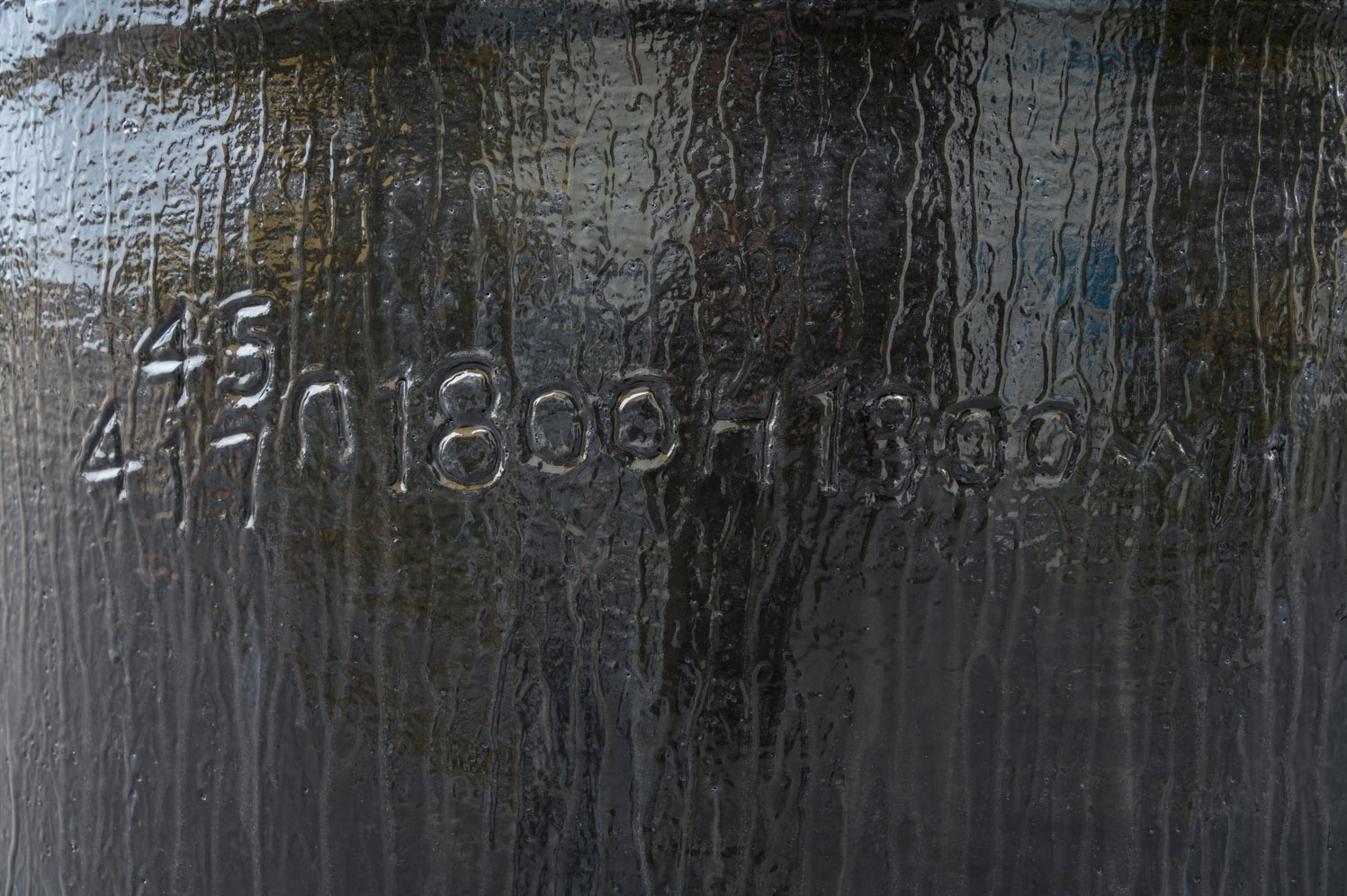

5. Rigorous Quality Inspection

Unique tracking code for full lifecycle traceability

.

4. Surface Enhancement

Anti-oxidation coating → 3× improved corrosion resistance

.

6. Safety Packaging

Shock-absorbent layer + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

Suitable for most non-ferrous metals

Melt Aluminium

Melt Copper

Melt Gold

WHY CHOOSE US

FAQS

Q1: Can The Crucible Cover reduce energy costs?

A: Absolutely! It reduces heat loss, cutting energy consumption by up to 30%.

Q2: What furnaces are compatible?

A: It’s versatile—suitable for induction, gas, and electric furnaces.

Q3: Is graphite silicon carbide safe for high temperatures?

A: Yes. Its thermal and chemical stability makes it perfect for extreme conditions.

Q4: How to prevent crucible cracking?

Never charge cold material into a hot crucible (max ΔT < 400°C).

Cooling rate after melting < 200°C/hour.

Use dedicated crucible tongs (avoid mechanical impact).

Q5: How to prevent crucible cracking?

Never charge cold material into a hot crucible (max ΔT < 400°C).

Cooling rate after melting < 200°C/hour.

Use dedicated crucible tongs (avoid mechanical impact).

Q6: What payment methods does your company accept?

We offer multiple payment options to accommodate different order sizes. For small orders, we accept Western Union and PayPal. For bulk orders, we require 30% payment by T/T in advance, with the remaining balance cleared prior to shipment.

Q7:How to deal with the faulty?

We produced in strict quality control systems, with a defective rate of less than 2%. If there are any problems with the product, we will provide free replacement.

Q8:Can we visit your company?

Yes, you are welcomed at any time.

Case Study #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Case Study #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Testimonials

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe