Introduction to Aluminum Casting and Riser Tubes

Aluminum, the most abundant metallic element in Earth's crust after oxygen and silicon, has become indispensable in modern engineering applications. Its competitive advantages make it the second most widely used metal after steel in industrial applications.

In aluminum casting production, molten aluminum or aluminum alloy is poured into sand or metal molds to create components of various shapes and sizes. The standard production process includes:

- Material preparation

- Furnace charging

- Melting

- Stirring

- Alloy mixing

- Converter processing

- Precision alloy adjustment

- Aluminum liquid refinement

- Precision filtration

- Casting

- Homogenization

- Sawing

Low-Pressure Casting: The Preferred Aluminum Casting Method

Among various casting techniques, low-pressure casting has emerged as the primary method for aluminum alloy components. This process fills molds with molten metal under controlled pressure, offering several key advantages:

- Smooth metal filling ensures consistent mold filling

- Excellent formability produces components with clear contours and smooth surfaces

- Dense microstructure enhances mechanical properties

- High metal yield improves production efficiency

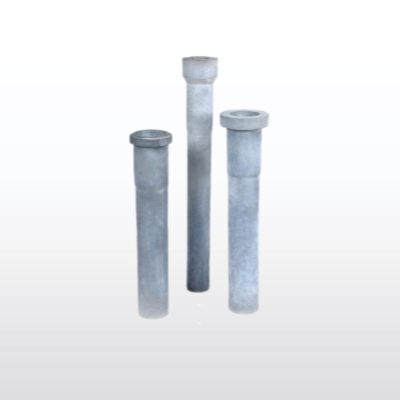

The Critical Role of Riser Tubes in Casting Systems

The riser tube serves as one of the most crucial components in low-pressure casting machines. Installed on the casting equipment with its lower end immersed in the alloy melting device, it extracts molten aluminum alloy (approximately 700°C) from the bottom of the melting apparatus for casting automotive wheels, engine cylinder heads, and other critical components.

During continuous production, riser tubes must withstand:

- Repeated pressure fluctuations

- Thermal shocks from molten metal flow

- Prolonged high-temperature exposure

- Continuous erosion and冲刷

To meet these demanding conditions, high-quality riser tubes must possess:

- Excellent resistance to aluminum alloy corrosion

- Superior thermal shock resistance

- Reliable air tightness

- Exceptional thermal fatigue resistance

Comprehensive Comparison of Riser Tube Materials

Currently, riser tubes for aluminum alloy low-pressure casting fall into two main categories:

1. Metal Riser Tubes (Cast Iron/Stainless Steel)

Advantages:

- Good mechanical properties

- Excellent air tightness

- Easy processing

- Low cost

Disadvantages:

- Significant erosion from prolonged aluminum alloy exposure

- Contaminates cast products

- Short service life

2. Non-Metal Riser Tubes

Graphite:

- Poor oxidation resistance

- Low wear resistance

- Short lifespan

Titanium Aluminum Oxide:

- Moderate strength

- Inferior thermal shock resistance compared to silicon nitride alternatives

Silicon Nitride-Bonded Silicon Carbide:

- High strength

- Excellent thermal shock resistance

- Good aluminum erosion resistance

- Moderate air tightness

Silicon Nitride (Si₃N₄): The Premium Riser Tube Material

Silicon nitride ceramic stands out with exceptional properties:

- High strength and hardness (HRA91-93)

- Maintains performance at 1300-1400°C

- Low friction coefficient

- Self-lubricating properties

- Excellent wear resistance

- Strong corrosion resistance (resists all inorganic acids except HF)

- Outstanding thermal shock resistance

- Minimal high-temperature creep

These characteristics make Si₃N₄ the ideal material for premium riser tubes.

Key Advantages of Silicon Nitride Riser Tubes:

- High temperature and corrosion resistance

- Low thermal expansion coefficient

- Exceptional thermal stability

- Long service life

Cost Considerations:

While silicon nitride riser tubes have higher initial costs due to:

- Expensive high-purity raw materials

- Complex manufacturing processes

- Difficult machining requirements

Their long-term benefits outweigh the costs:

- 5-20x longer lifespan than conventional tubes

- Reduced replacement frequency

- Improved production continuity

- Enhanced automation potential

Counter-Gravity Casting and Riser Tube Applications

Counter-gravity casting (CGC), developed in the 1950s, has become mainstream for high-quality aluminum-magnesium alloy castings, particularly for large, complex thin-walled components.

How Counter-Gravity Casting Works:

- Metal rises through riser tube against gravity

- Precise pressure control enables customized filling speeds

- Solidification under pressure reduces defects

Riser Tube Requirements in CGC:

- Must withstand 700-900°C aluminum melt

- Requires low thermal expansion coefficient

- Needs excellent thermal shock resistance

Riser Tube Material Options for Counter-Gravity Casting

1. Metal Riser Tubes

- Typically made from cast iron or steel with refractory coatings

- Prone to coating peeling and metal corrosion

- Short service life affects production efficiency

2. Titanium Aluminum Oxide Ceramic

- High melting point (1860°C)

- Low thermal expansion (α≤2.0×10⁻⁶/K)

- Moderate service life (3+ months for quality products)

3. Silicon Nitride Ceramic

- Exceptional thermal shock resistance

- Long lifespan (14+ months for premium tubes)

- Higher cost but excellent performance

4. Sialon Ceramic

- Combines silicon nitride and alumina advantages

- 12-month service life potential

- Good thermal and mechanical properties

5. Composite Riser Tubes

- Combine metal and ceramic benefits

- Customizable designs

- Higher manufacturing complexity

Conclusion: Selecting the Optimal Riser Tube

For foundries seeking maximum performance and efficiency, silicon nitride riser tubes represent the ultimate solution. While their initial cost is higher, their extended service life and superior performance deliver significant long-term value, making them the smart choice for modern aluminum casting operations.

Post time: May-25-2025