Carbon Bonded Silicon Carbide Crucibles

Features

Melting metals and alloys: Graphite SiC Crucibles are used in the melting metals and alloys, including copper, aluminum, zinc, gold, and silver. The high thermal conductivity of graphite SiC crucibles ensures fast and uniform heat transfer,while the high melting point of SiC provides excellent thermal stability and resistance to thermal shock.

Semiconductor manufacturing: Graphite SiC crucibles can be used for the manufacturing semiconductor wafers and other electronic components. Graphite SiC Crucibles’ high thermal conductivity and stability make them ideal for use in high-temperature processes such as chemical vapor deposition and crystal growth.

Research and development: Graphite SiC crucibles are used in materials science research and development,where purity and stability are essential. They are used in the synthesis of advanced materials such as ceramics, composites, and alloys.

1.Quality raw materials: Our SiC Crucibles are made using high-quality raw materials.

2.High mechanical strength: Our crucibles have high mechanical strength at high temperatures, ensuring durability and longevity.

3.Excellent thermal performance: Our SiC crucibles provide excellent thermal performance, ensuring that your materials melt quickly and efficiently.

4.Anti-corrosion properties: Our SiC Crucibles have anti-corrosion properties, even at high temperatures.

5.Electrical insulation resistance: Our crucibles have excellent electrical insulation resistance, preventing any potential electrical damage.

6.Professional technology support: We offer professional technology to support our customers are satisfied with their purchases.

7.Customization available: We provide customization options to our customers.

Silicon carbide crucible, also known as carbon bonded silicon carbide crucible, is an essential furnace container widely used in laboratories and various industrial production processes. These crucibles are made of silicon carbide material and have excellent resistance to high temperatures, oxidation and corrosion. This, in turn, allows the crucible to withstand wear and corrosion even under extreme high-temperature conditions.

One of the distinguishing features of silicon carbide crucibles is their chemical inertness. They also have excellent electrical insulation properties and exhibit impressive thermal conductivity. These crucibles are heat-resistant to temperatures exceeding 2000°C, making them ideal for melting point determination and heat treatment experiments involving ultra-high temperature materials or chemical reagents.

Silicon carbide crucibles are widely used in various fields. In chemistry laboratories, they are often used for high temperature reactions and experiments. Some specific uses include the preparation of molten samples, the melting of specialty glass fibers, and the processing of fused silica. They can also facilitate processes such as casting, sintering and heat treatment.

In addition to laboratory applications, silicon carbide crucibles also play a vital role in industrial production. In the fields of steel smelting, metal manufacturing, semiconductor processing, polymer material processing and other fields, the crucible is an indispensable tool.

When using silicon carbide crucibles, there are some precautions that need to be taken to ensure optimal performance:

1. Before first use, the crucible must be thoroughly cleaned and preheated in the temperature range of 200℃-300℃ for 2-3 hours. This process eliminates any remaining impurities and moisture, minimizing the risk of damage caused by thermal expansion and contraction.

2. When placing substances in the crucible for processing, do not exceed the capacity of the crucible. This ensures proper circulation of air within the furnace and ensures uniform reaction of the materials.

3. Care must be taken when placing the crucible into the heating device. Controlling heating speed and temperature is critical to prevent rapid or excessive temperature changes that can cause potential damage.

In summary, silicon carbide crucibles are versatile and durable tools with important applications in both laboratory and industrial settings. These crucibles offer excellent thermal resistance and chemical inertness, providing a reliable and efficient way to conduct high-temperature reactions and experiments. Correct use and care ensure optimal performance and extend the service life of these indispensable crucibles.

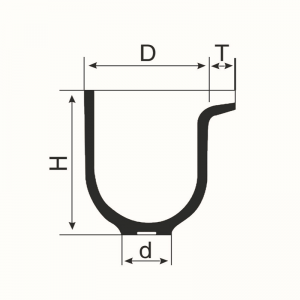

|

Item |

Outer Diameter |

Height |

Inside Diameter |

Bottom Diameter |

|

Z803 |

620 |

800 |

536 |

355 |

|

Z1800 |

780 |

900 |

680 |

440 |

|

Z2300 |

880 |

1000 |

780 |

330 |

|

Z2700 |

880 |

1175 |

780 |

360 |