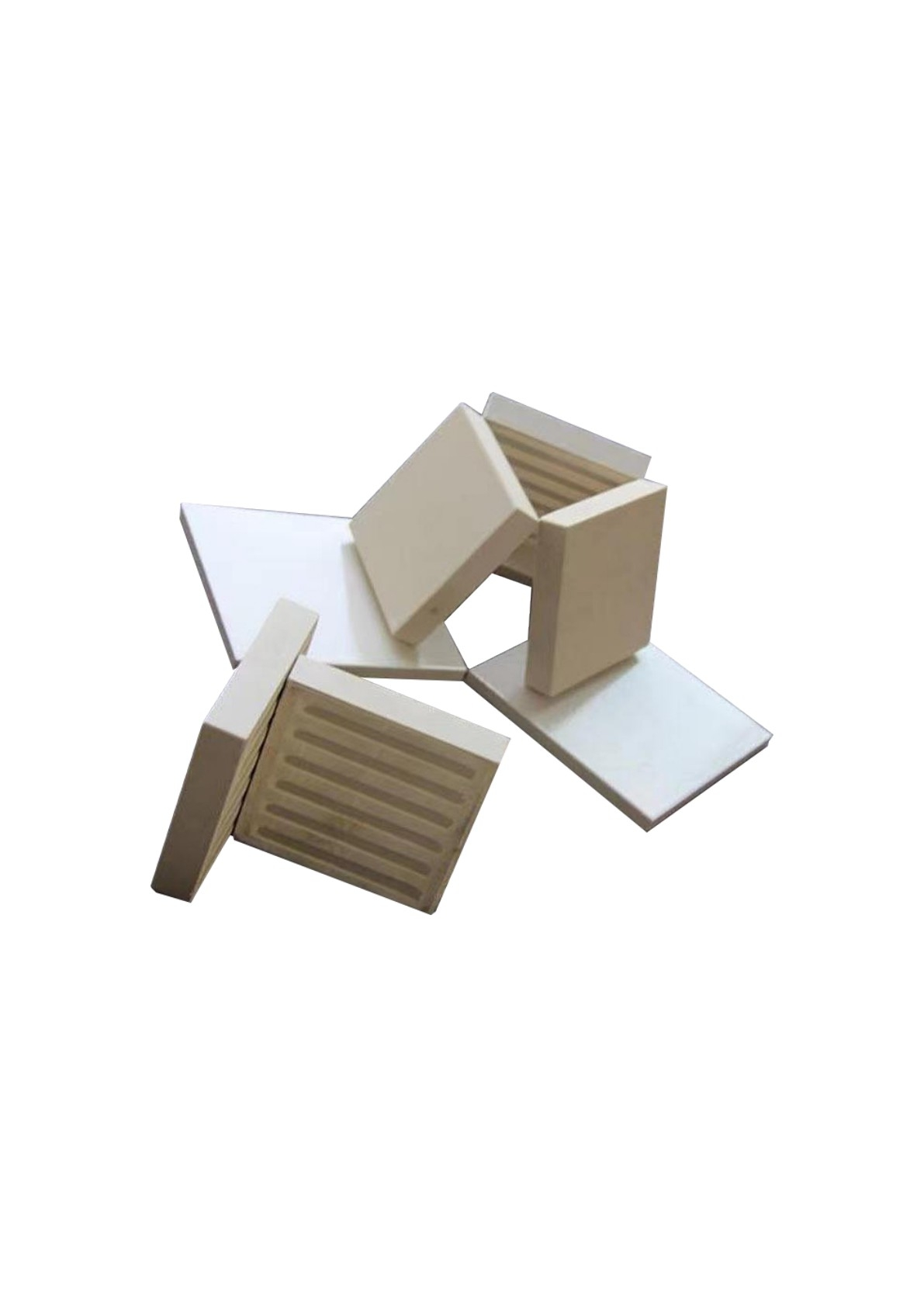

Aluminum titanate ceramic gate sleeve

Features

● In the aluminum processing industry, there are many processes and components involved in the transportation and control of molten aluminum, such as joints, nozzles, tanks and pipes. In these processes, the use of aluminum titanate ceramics with low thermal conductivity, high thermal shock resistance, and non-stick molten aluminum is the future trend.

● Compared with aluminum silicate ceramic fiber, TITAN-3 aluminum titanate ceramic has higher strength and better non-wetting property. When used for plugs, sprue tubes and hot top risers in the foundry industry, it has higher reliability and longer service life.

● All kinds of riser tubes used in gravity casting, differential pressure casting and low pressure casting have high requirements on insulation, thermal shock resistance and non-wetting property. Aluminum titanate ceramics are the best choice in most cases.

● The flexural strength of aluminum titanate ceramics is only 40-60MPa, please be patient and meticulous during installation to avoid unnecessary external force damage.

● In applications where a tight fit is required, slight variations can be carefully polished with sandpaper or abrasive wheels.

● Before installation, it is recommended to keep the product free from moisture and dry it in advance.