Graphite crucibles are essential tools in various industries, particularly in metal smelting and purification processes. However, improper handling can lead to damages or safety hazards. To ensure the longevity and effectiveness of graphite crucibles, it is crucial to follow correct handling methods. Here are some guidelines to consider:

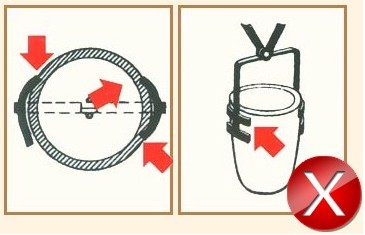

Incorrect Practices:

Using undersized crucible tongs can cause dents and indentations on the crucible's surface, especially if excessive force is applied during gripping. Moreover, positioning the tongs too high while removing the crucible from the furnace can result in breakage.

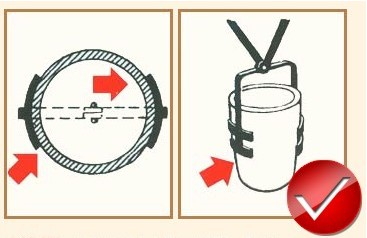

Correct Practices:

Crucible tongs should be appropriately sized to match the crucible. Undersized tongs must be avoided. Additionally, when gripping the crucible, the tongs should hold it slightly below the center to ensure even distribution of force.

To prevent premature crucible damage and potential accidents, it is essential to adhere to the following precautions:

The dimensions of the crucible tongs must match the size of the crucible, ensuring complete contact with the crucible's interior.

The handle of the tongs should not exert pressure on the upper rim of the crucible during gripping.

The crucible should be gripped slightly below the center, allowing for uniform force distribution.

Acceptance and Handling of Silicon Carbide Graphite Crucibles

Acceptance of Goods: Upon receiving silicon carbide graphite crucibles, it is crucial to inspect the outer packaging for any signs of damage. After unpacking, examine the crucible's surface for any defects, cracks, or damage to the coating.

Crucible Handling: Incorrect Practice: Handling the crucible by striking or rolling it can cause damage to the glaze layer.

Correct Practice: Crucibles should be handled carefully using a cushioned cart or suitable handling tools to avoid impacts, collisions, or dropping. To safeguard the glaze layer, the crucible must be handled gently, ensuring it is lifted and placed with care. Rolling the crucible on the ground during transportation should be strictly avoided. The glaze layer is susceptible to damage, leading to oxidation and aging during usage. Therefore, it is recommended to use a cushioned cart or other appropriate handling tools to ensure careful transportation of the crucible.

Storage of Silicon Carbide and Graphite Clay Crucibles: The storage of crucibles is particularly vulnerable to moisture damage.

Incorrect Practice: Stacking crucibles directly on a cement floor or exposing them to moisture during storage or transportation.

Correct Practice:

Crucibles should be stored in a dry environment, preferably on wooden pallets, ensuring proper ventilation.

When the crucibles are placed upside down, they can be stacked to save space.

Crucibles must never be exposed to humid conditions. Moisture absorption can cause the glaze layer to peel off during the preheating stage, leading to decreased efficiency and lifespan. In severe cases, the bottom of the crucible may detach.

Our company specializes in the production of silicon carbide graphite crucibles, specialized aluminum melting crucibles, copper graphite crucibles, graphite clay crucibles, export-oriented graphite crucibles, phosphorus conveyors, graphite crucible bases, and protective sleeves for thermocouples. Our products undergo rigorous selection and assessment, ensuring optimal performance from the choice of raw materials to every production detail and packaging design.

Post time: Jun-27-2023