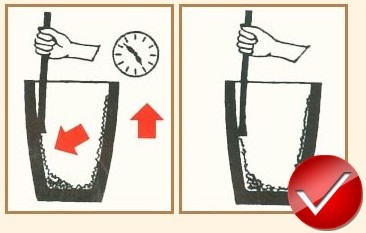

1. Slag removal of graphite crucible

Wrong approach: residual additives in the crucible will penetrate the crucible wall and corrode the crucible, thus shortening the life of the crucible.

Correct method: You must use a steel shovel with a flat bottom every day to carefully scrape off the residue on the inner wall of the crucible.

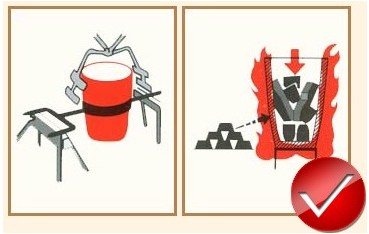

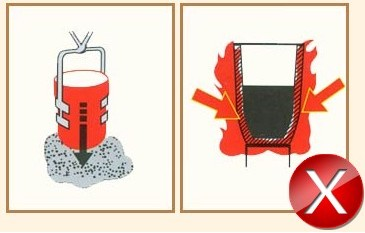

2. The emptying of the graphite crucible

Wrong way: hang the hot crucible out of the furnace and put it on the sand, the sand will react with the glaze layer of the crucible to form slag; the residual metal liquid will solidify in the crucible after the crucible is shut down, and the metal will be melted during the next heating. The expansion will burst the crucible.

The correct way: after the hot crucible is lifted out of the furnace, it should be placed on a high-temperature resistant plate, or suspended on a transfer tool; when production is interrupted due to furnace or other problems, the liquid metal should be poured into a mold (a small ingot mold) to form an ingot ingots, as small ingots can be reused more easily. Precautions:

Never allow residual liquid metal to freeze in the crucible. It is possible to dump the liquid and carry out slag cleaning when changing shifts.

If the liquid metal solidifies in the crucible, when reheated, the expanding metal will burst the crucible, sometimes even breaking the bottom of the crucible entirely.

Post time: Aug-31-2023