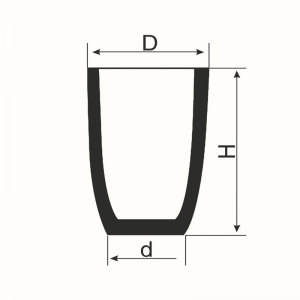

Material:

Our Cylindrical Crucible is crafted from isostatically pressed silicon carbide graphite, a material that offers exceptional high-temperature resistance and excellent thermal conductivity, making it an essential tool for industrial smelting applications.

- Silicon Carbide (SiC): Silicon carbide is known for its extreme hardness and excellent resistance to wear and corrosion. It can withstand high-temperature chemical reactions, offering superior stability even under thermal stress, which reduces the risk of cracking during sudden temperature changes.

- Natural Graphite: Natural graphite delivers exceptional thermal conductivity, ensuring rapid and uniform heat distribution throughout the crucible. Unlike traditional clay-based graphite crucibles, our cylindrical crucible uses high-purity natural graphite, which improves heat transfer efficiency and reduces energy consumption.

- Isostatic Pressing Technology: The crucible is formed using advanced isostatic pressing, ensuring uniform density with no internal or external defects. This technology enhances the strength and crack resistance of the crucible, extending its durability in high-temperature environments.

Performance:

- Superior Thermal Conductivity: The Cylindrical Crucible is made from high thermal conductivity materials that allow for rapid and even heat distribution. This enhances the efficiency of the smelting process while reducing energy consumption. Compared to conventional crucibles, thermal conductivity is improved by 15%-20%, leading to significant fuel savings and faster production cycles.

- Excellent Corrosion Resistance: Our silicon carbide graphite crucibles are highly resistant to the corrosive effects of molten metals and chemicals, ensuring the stability and longevity of the crucible during prolonged use. This makes them ideal for smelting aluminum, copper, and various metal alloys, reducing maintenance and replacement frequency.

- Extended Service Life: With its high-density and high-strength structure, the lifespan of our cylindrical crucible is 2 to 5 times longer than traditional clay graphite crucibles. The superior resistance to cracking and wear extends operational life, lowering downtime and replacement costs.

- High Oxidation Resistance: A specially formulated material composition effectively prevents oxidation of the graphite, minimizing degradation at high temperatures and further extending the crucible's life.

- Superior Mechanical Strength: Thanks to the isostatic pressing process, the crucible boasts exceptional mechanical strength, retaining its shape and durability in high-temperature environments. This makes it ideal for smelting processes requiring high pressure and mechanical stability.

Product Advantages:

- Material Benefits: The use of natural graphite and silicon carbide ensures high thermal conductivity and corrosion resistance, providing lasting performance in harsh, high-temperature environments.

- High-Density Structure: Isostatic pressing technology eliminates internal voids and cracks, significantly improving the crucible’s durability and strength during extended use.

- High-Temperature Stability: Capable of withstanding temperatures up to 1700°C, this crucible is ideal for various smelting and casting processes involving metals and alloys.

- Energy Efficiency: Its superior heat transfer properties reduce fuel consumption, while the environmentally friendly material minimizes pollution and waste.

Choosing our high-performance Cylindrical Crucible will not only enhance your smelting efficiency but also reduce energy consumption, extend equipment lifespan, and lower maintenance costs, ultimately improving production efficiency.

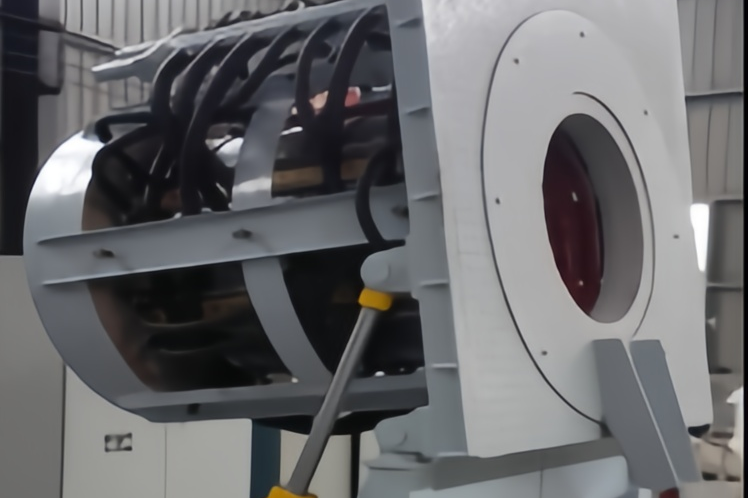

In modern metalworking and recycling industries, induction heating has become the preferred method for efficient and precise melting processes. The choice of crucible plays a critical role in ensuring that these processes run smoothly, especially in induction furnaces. We have developed Induction Heating Crucibles using isostatic pressing technology to provide unmatched performance in these demanding applications.

Unlike standard crucibles, which may struggle with the magnetic fields in induction furnaces, our crucibles are designed to generate heat through magnetic induction. This innovation not only enhances energy efficiency but also extends the lifespan of the crucible, making it the ideal choice for industries such as aluminum recycling and metal casting.

The magnetic properties of these crucibles are particularly important for users of induction furnaces, where the ability to conduct heat through induction can dramatically increase the overall efficiency of the process. This not only saves time but also reduces energy costs, making it a cost-effective solution for businesses.

Applications of Induction Heating Crucibles

- Aluminum Recycling Industry:

- In the recycled aluminum industry, corrosion resistance is critical due to the harsh conditions involved in the process. Our crucibles are specially designed to handle these environments, offering a lifespan that exceeds European crucibles by more than 20%.

- The high thermal conductivity ensures faster melting times, which boosts productivity and reduces energy consumption.

- Induction Furnaces:

- Traditional crucibles often lack magnetic properties, which can result in inefficiencies when used in induction furnaces. Our induction heating crucibles are engineered with magnetic heating capabilities, meaning the crucible itself generates heat, improving overall process efficiency and further reducing energy costs.

- With a lifespan of over one year, these crucibles significantly outlast their counterparts, reducing downtime and replacement costs.

- Other Metal Melting Applications:

- Whether for copper, zinc, or silver melting processes, our crucibles provide reliable performance, ensuring consistent results across various industries.

Maintenance and Usage Tips for Induction Heating Crucibles

To maximize the lifespan and efficiency of your Induction Heating Crucible, it’s important to follow proper usage and maintenance practices:

- Preheating: Gradually heat the crucible to the desired temperature to avoid thermal shock.

- Cleaning: Regularly clean the crucible to remove residues that could impact performance and shorten the lifespan.

- Storage: Store crucibles in a dry, cool environment to prevent exposure to moisture or corrosive elements that could degrade the material over time.

These practices will help ensure that your crucible operates at peak efficiency for longer, reducing the frequency of replacements and maintenance.

Product Promotion

We are proud to offer Induction Heating Crucibles designed for maximum durability and performance. Our crucibles feature isostatic pressing technology, which ensures uniformity and strength, making them more resistant to thermal shock and mechanical stress. With the ability to generate heat through magnetic induction, our crucibles are tailored specifically for induction furnace applications, where precision and energy efficiency are paramount.

Customization Options: We understand that every industry has unique requirements. That’s why we offer fully customizable crucibles, tailored to meet your specific operational needs. Whether you need a different shape, size, or composition, our team is ready to work with you to create the perfect solution.

Technical Support: Our dedicated team provides full technical support to help you get the most out of your crucibles. From initial installation to ongoing maintenance advice, we are here to ensure that your processes run smoothly and efficiently.

Call to Action

If you are looking to enhance the efficiency of your induction heating processes, our Induction Heating Crucibles are the perfect solution. With isostatic pressing technology, superior magnetic heating properties, and an extended lifespan, these crucibles offer the reliability and performance your business needs to stay ahead in a competitive market.

Contact us today to learn more about our customized crucible solutions and how they can improve your production processes.