Crucibles for upcast and copper casting machine

Where You Can Use It:

- For Brass Casting: Perfect for making continuous castings with brass.

- For Red Copper Casting: Designed for red copper casting, ensuring top-quality results.

- For Jewelry Casting: Ideal for crafting jewelry from gold, silver, platinum, and other precious metals.

- For Steel and Stainless Steel Casting: Built for casting steel and stainless steel with precision.

Types Based on Shape:

- Round Bar Mould: For producing round bars in various sizes.

- Hollow Tube Mould: Great for creating hollow tubes.

- Shaped Mould: Used for casting products with unique shapes.

The use of graphite materials and isostatic pressing enables our crucibles to have a thin wall and high thermal conductivity, ensuring fast heat conduction. Our crucibles can withstand high temperatures ranging from 400-1600℃, providing reliable performance for various applications. We use only the main raw materials of well-known foreign brands and imported raw materials for our glazes, ensuring stable and reliable quality.

What is the loading capacity per batch?

What is the heating mode? Is it electric resistance, natural gas, LPG, or oil? Providing this information will help us give you an accurate quote.

|

Item |

Code |

Height |

Outer Diameter |

Bottom Diameter |

|

CU210 |

570# |

500 |

605 |

320 |

|

CU250 |

760# |

630 |

610 |

320 |

|

CU300 |

802# |

800 |

610 |

320 |

|

CU350 |

803# |

900 |

610 |

320 |

|

CU500 |

1600# |

750 |

770 |

330 |

|

CU600 |

1800# |

900 |

900 |

330 |

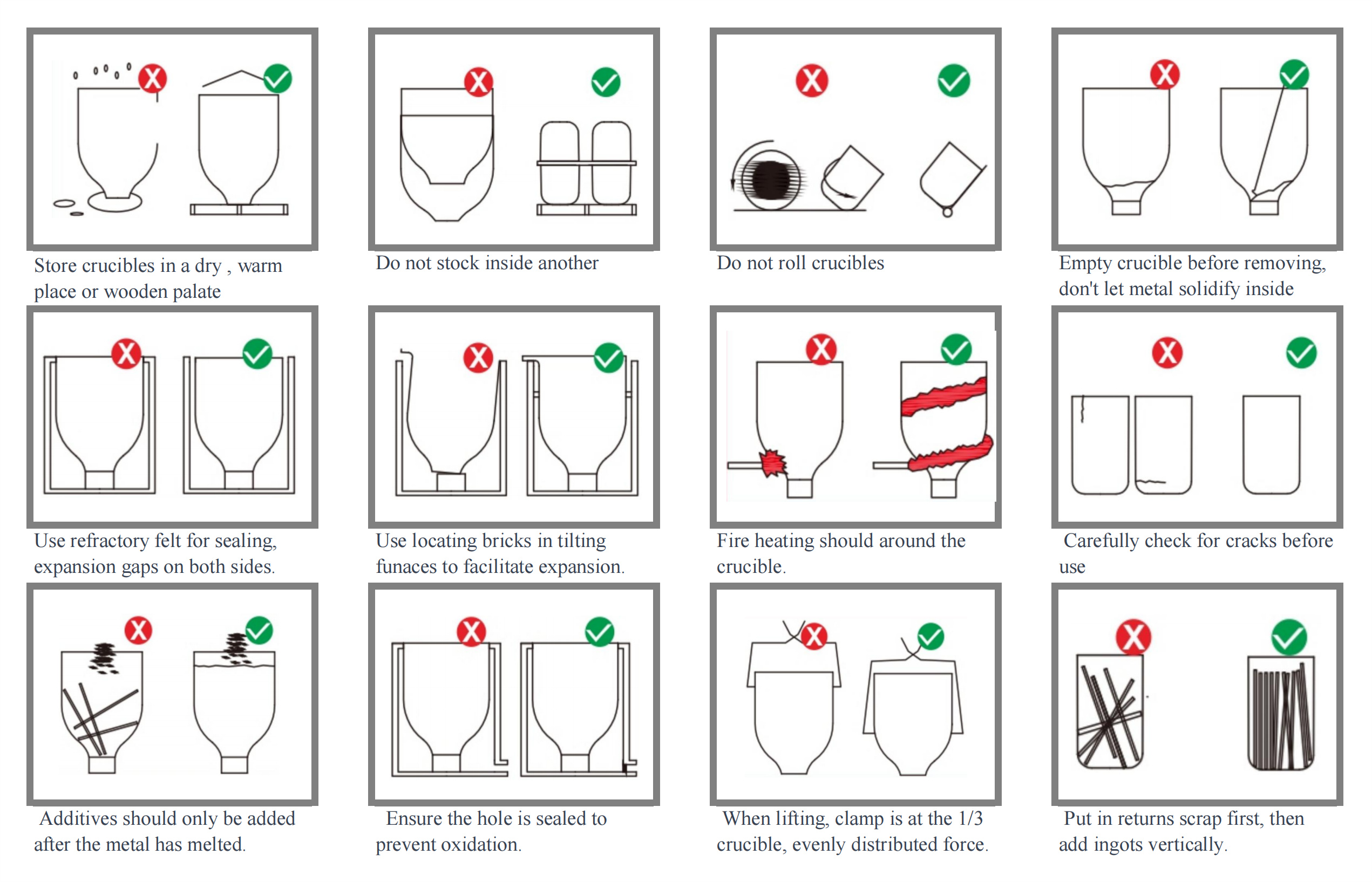

1.Place the crucible in a dry area or within a wooden frame to prevent moisture accumulation.

2.Use crucible tongs that match the shape of the crucible to avoid causing damage to it.

3.Feed the crucible with an amount of material that is within its capacity; avoid overloading it to prevent bursting.

4.Tap the crucible while removing slag to prevent damage to its body.

5.Place kelp, carbon powder, or asbestos powder on the pedestal and ensure that it matches the bottom of the crucible. Put the crucible at furnace’s center.

6.Keep a safe distance from the furnace, and secure crucible firmly with a wedge.

7.Avoid using an excess amount of oxidizer to extend the life of the crucible.

Do you offer OEM manufacturing?

--Yes! We can manufacture products to your requested specifications.

Can you arrange delivery through our shipping agent?

--Absolutely, we can arrange delivery through your preferred shipping agent.

What is your delivery time?

--Delivery in stock products typically takes 5-10 days . It may take 15-30 days for customized products.

How about your working hours?

--Our customer service team is available in 24h. We will be happy to reply you at anytime.