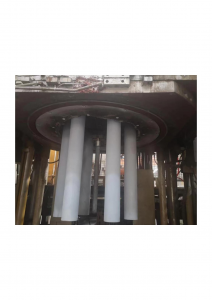

Aluminum titanate ceramic riser

Features

● The thermal insulation performance of the riser directly affects the defect rate of differential pressure and low pressure castings. Among the available materials, aluminum titanate ceramics are ideal due to their low thermal conductivity, high thermal shock resistance, and non-wetability with molten aluminum.

● The low thermal conductivity and non-wetting properties of aluminum titanate can effectively reduce the slagging on the upper part of the riser tube, ensure the filling of the cavity, and improve the quality stability of the casting.

● Compared with cast iron, carbon nitrogen, and silicon nitride, aluminum titanate has the best thermal shock resistance, and no preheating treatment is required before installation, which reduces labor intensity.

● Among several commonly used aluminum liquid impregnating materials, aluminum titanate has the best non-wetting property, and no coating agent is needed to avoid pollution to aluminum liquid.

● Due to the low bending strength of aluminum titanate ceramics, it is necessary to be patient when adjusting the flange during installation to avoid over-tightening or eccentricity.

● In addition, due to its low bending strength, care should be taken to avoid external force impacting the pipe when cleaning the surface slag.

● Aluminum titanate risers should be kept dry before installation, and should not be used in wet or water-stained environments.