Wholesale Silicon carbide graphite crucible

Features

Product Description

Our graphite crucible is mainly composed of natural flake graphite and binder, which has excellent thermal conductivity, high temperature resistance, good thermal stability, and does not react with molten materials. Widely used in non-ferrous metal casting. However, it is easy to oxidize under high temperature and strong oxidizing atmosphere, so it should be used in an environment without strong oxidants to maximize its service life. With the advancement of production technology, some of our graphite crucibles are coated with multiple layers of glaze on the surface to prevent oxidation and enhance corrosion resistance.

- High thermal conductivity: Use high thermal conductivity materials such as graphite to reduce melting time.

- Thermal shock resistance: It has strong thermal shock resistance and is not prone to cracks when heated or cooled rapidly.

- High heat resistance: can withstand temperatures from 1200 to 1650°C.

- Corrosion resistance: Resistant to erosion by molten materials.

- Mechanical impact resistance: Exhibits a certain degree of resistance to mechanical impact, for example during pouring of molten material.

- Anti-oxidation: After treatment, it minimizes oxidation when exposed to oxidants at high temperatures and reduces oxidation consumption.

- Anti-adhesion: The non-adhesion properties of graphite reduce the penetration and adhesion of molten materials.

- Minimal metal contamination: It contains almost no impurities that may contaminate the molten material, thus minimizing metal contamination.

- Resistant to the influence of flux: It shows good resistance to the influence of flux and slag remover.

Our graphite crucibles are designed to meet the demanding requirements of high temperature metal casting applications, delivering exceptional performance and reliability.

Product Description:

Our carbon-silicon carbide graphite crucibles offer superior performance and durability, surpassing standard graphite crucibles in several key ways.

1) Superior crack resistance, corrosion resistance and oxidation resistance: The quality of our carbon silicon carbide graphite crucible is 5-10 times that of ordinary graphite crucibles, ensuring excellent durability and corrosion resistance and oxidation resistance.

2) Enhanced thermal conductivity and energy efficiency: Our crucible has excellent heat transfer performance and high thermal conductivity, significantly shortening melting time and saving energy, saving 2/5 to 1/3 energy than traditional crucibles.

3) Extended service life: When used strictly in accordance with our operating instructions, our crucibles have a 6-month warranty from the date of purchase. If product quality issues are confirmed, we offer free replacement or discounts.

4) Increased efficiency: Our crucibles reduce downtime and associated costs, improving overall operational efficiency.

Our graphite crucible raw materials are added with different amounts of silicon carbide particles (such as 50% or 24%) and can be customized according to customers' specific requirements. The introduction of different contents of silicon carbide results in crucibles with different silicon carbide contents.

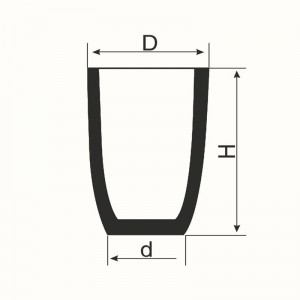

Main specifications:

- Temperature resistance: ≥ 1630°C (specific models ≥ 1635°C)

- Carbon content: ≥ 38% (specific models ≥ 41.46%)

- Apparent porosity: ≤ 35% (specific models ≤ 32%)

- Bulk density: ≥ 1.6g/cm3 (specific models ≥ 1.71g/cm3)

Our carbon-silicon carbide graphite crucibles are engineered for exceptional performance, longevity and efficiency, making them ideal for high temperature applications across a variety of industries.