When it comes to high-temperature processing, sintering, heat treatment and crystal growth of metals, ceramics and other materials, the choice of crucible plays a vital role. Crucibles are important vessels used in a variety of industrial processes, and choosing the right crucible material can significantly affect the efficiency and results of these processes. In this product introduction, we will explore the differences between silicon carbide and graphite crucibles, focusing on their unique characteristics, service life, price, and range of applications.

Silicon carbide crucible:

Silicon carbide crucibles are made of silicon carbide material, which is known for its excellent high temperature resistance and corrosion resistance. These crucibles are widely used in high-temperature sintering, heat treatment and crystal growth processes of metals, ceramics and other materials. The rugged properties of silicon carbide make it ideal for applications where extreme temperatures and corrosive environments are common. However, it should be noted that compared with graphite crucibles, silicon carbide crucibles have a relatively short service life, especially under high temperature and corrosive conditions. The tendency of silicon carbide crucibles to oxidize and ablate will affect their service life. Although silicon carbide crucibles have a shorter service life, they are indispensable in industries that require processing of highly corrosive and high-temperature materials, making them the first choice for electronic and optoelectronic manufacturing applications.

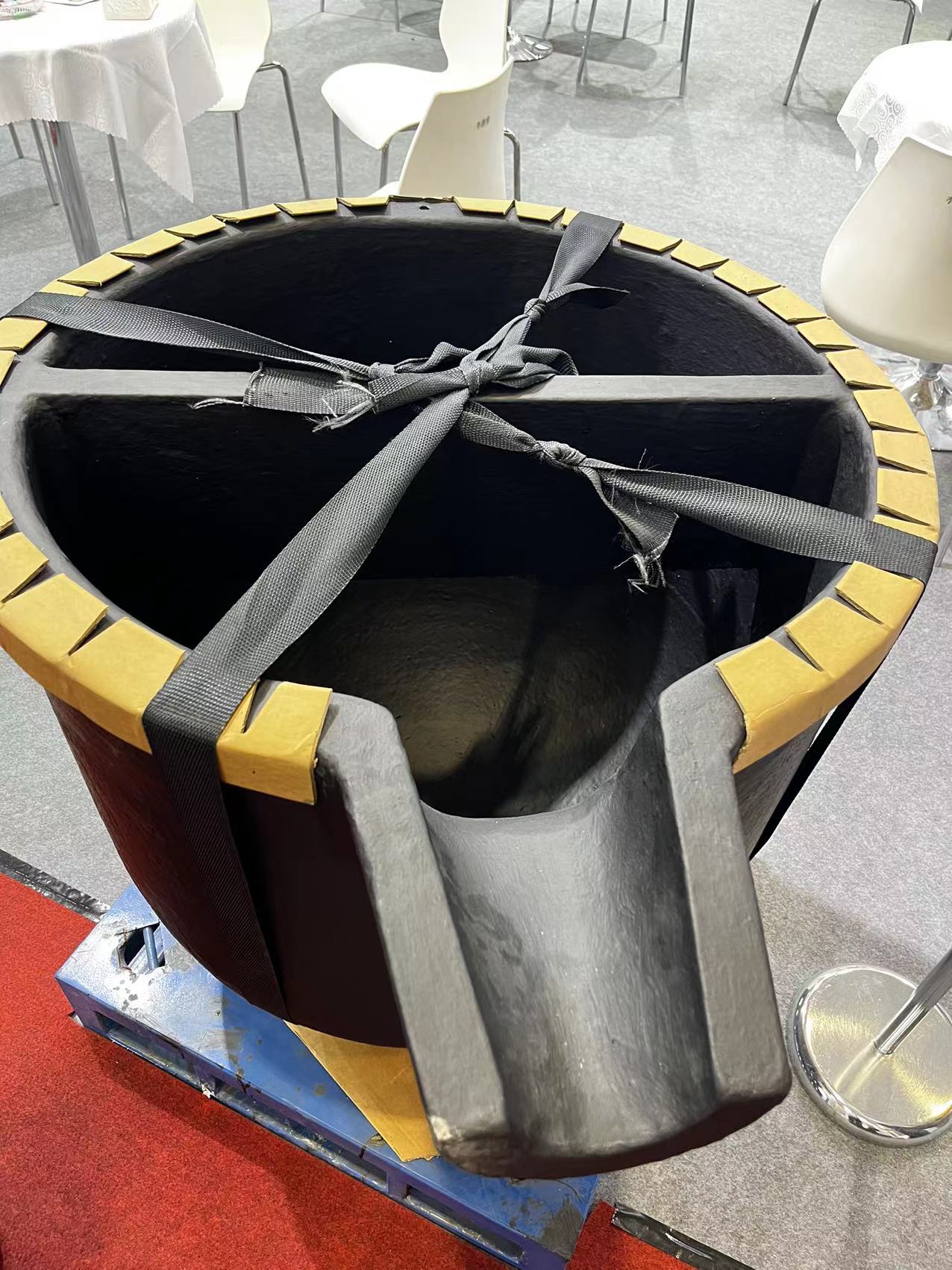

Graphite crucible:

In contrast, graphite crucibles are made of graphite material and are widely used in the processing of metallic and non-metallic materials. Graphite crucibles are known for their excellent resistance to oxidation, ablation and high temperature, resulting in significantly longer service life compared to silicon carbide crucibles. This durability makes graphite crucibles a cost-effective choice for applications involving heat treatment and crystal growth of a variety of materials. The affordability of graphite crucibles, coupled with their long service life, makes them a popular choice for those industries looking for reliable and durable crucibles in their manufacturing processes.

Choose the right crucible:

The choice between silicon carbide and graphite crucibles ultimately depends on the specific requirements of the application. Although silicon carbide crucibles have excellent resistance to high temperatures and corrosive environments, they are more expensive due to manufacturing processes and material costs. Graphite crucibles, on the other hand, are more economical, have a longer service life, and are suitable for a wide range of applications, especially those involving general material processing, heat treatment, and crystal growth.

To sum up, silicon carbide crucibles and graphite crucibles have their own advantages and disadvantages. When selecting a crucible for a specific application, specific operating conditions, material requirements, and budget constraints must be considered. For high-temperature, highly corrosive material processing, or manufacturing in the electronics and optoelectronics fields, silicon carbide crucibles are the first choice. In contrast, for heat treatment and crystal growth of common materials, graphite crucibles provide a cost-effective and durable solution.

At [your company name], we offer a full range of carbon graphite crucibles, graphite crucibles, silicon carbide graphite crucibles and silicon graphite crucibles to meet different industrial needs. Our crucibles are designed to the highest quality standards, ensuring optimal performance and reliability in a variety of manufacturing processes. Whether you need crucibles for high-temperature sintering, heat treatment or crystal growth, our product range offers the versatility and durability needed to support your operation.

Choose [Your Company Name] for high-quality crucibles with exceptional performance and service life, allowing you to achieve outstanding results in your industrial processes. Contact us today to explore our full range of crucibles and find the perfect solution for your specific application requirements.

Post time: Mar-27-2024