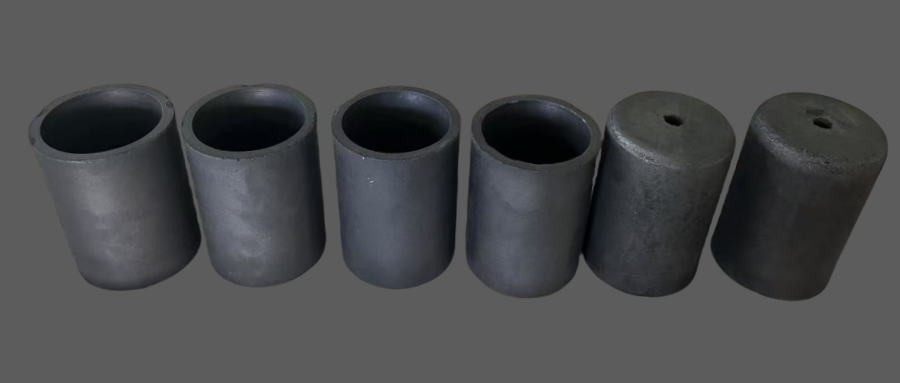

Graphite Protection Sleeve

PRODUCT FEATURES

Superior Oxidation Resistance

Exclusive formula and process fundamentally address the core weakness of ordinary graphite sleeves.

High Durability

Resists cracking and bursting, can be reused multiple times, offering extremely low cost per use.

Cost-Effective

Advanced manufacturing delivers premium performance at an accessible price point.

Detailed Product Introduction

Comprehensive Compatibility for Diverse Production Needs

Designed for upward casting technology, this product is perfectly suited for use with crystallizers producing round copper rods in various specifications (Φ8, Φ12.5, Φ14.4, Φ17, Φ20, Φ25, Φ32, Φ38, Φ42, Φ50, Φ100) and various special-shaped copper products.

Dual-Type Strategy (A/B) Tailored to Your Specific Needs

| Feature | Type B (Cost-Effective) | Type A (Premium Import Alternative) |

|---|---|---|

| Key Characteristic | Basic oxidation resistance, best value | Enhanced oxidation resistance, performance rivals imports |

| Material & Process | Quality graphite base, scientific formula | High-grade graphite base, advanced process & formula |

| Oxidation Resistance | Excellent - Minimal oxidation during use | Exceptional - Superior oxidation lifespan |

| Crack Resistance | High - Resists cracking and bursting | Very High - Exceptional mechanical & thermal stability |

| Reusability | Can be reused multiple times | Can be reused significantly more times, longer service life |

| Key Advantage | Overcomes all shortcomings of ordinary graphite (oxidation) and silicon carbide sleeves | Direct replacement for imported sleeves (e.g., from Finland, Scotland), drastically reduces procurement costs |

| Target Customer | Domestic copper producers seeking cost reduction, efficiency gains, and improved yield rates | High-volume producers with demanding uptime requirements, seeking reliable import substitution |

Product Features & Benefits

1. High-Purity Graphite Base: Ensures no contamination of molten copper, guaranteeing final product purity and conductivity.

2. Exclusive Anti-Oxidation Technology: Special impregnation process and treatment create a protective layer on the graphite surface, significantly delaying oxidation and extending service life.

3. Exceptional Thermal Shock Resistance: Withstands rapid temperature changes, safe for startup/shutdown, eliminates risk of cracking.

4. Precise Dimensional Design: Perfect compatibility with mainstream crystallizer equipment, easy installation, excellent sealing.

Professional Installation Guide

For best results, please follow these steps:

1. Install Thermal Barrier Sleeve: First, install the thermal barrier sleeve onto the crystallizer.

2. Install Protection Sleeve: Next, install our graphite protection sleeve. It should feel snug; avoid over-tightening. Never use hammers or tools to force it.

3. Install Graphite Die: Insert the graphite die, but do not fully tighten its thread; leave a gap of 2-3 threads.

4. Sealing: Wrap asbestos rope around the exposed 2-3 threads of the die for 2 cycles.

5. Final Tightening: Fully tighten the die's thread until it is tightly sealed against the bottom of the protection sleeve. It is now ready for use.

6. Replacement Tip: When replacing the die later, simply remove the old die and repeat steps 3-5. This method is convenient and helps prevent damage to the protection sleeve.

Graphite Protection Sleeve

Product overview

Graphite protective sleeves are precision manufactured to withstand extreme conditions and are ideal for protecting sensitive instruments such as temperature probes and thermocouples during high temperature operations.

Features

- Extreme high temperature resistance: Graphite protective sleeves can easily withstand temperatures up to 3000°C while maintaining material stability without deformation or performance degradation, making them ideal for applications such as metal smelting and glass manufacturing.

- Oxidation resistance: The natural oxidation resistance of graphite material allows the protective cover to maintain a long service life under high temperatures, reducing wear and maintenance costs caused by oxidation.

- Excellent corrosion resistance: Graphite material shows strong resistance to most acidic and alkaline chemicals, effectively protecting internal equipment from corrosive substances in the chemical and metallurgical industries.

- Superior thermal conductivity: The graphite protective sleeve has high thermal conductivity, which is conducive to rapid heat transfer and improves the accuracy of temperature probes and sensors, thereby improving measurement accuracy and equipment efficiency.

- Low thermal expansion: The low thermal expansion coefficient of graphite material can still ensure dimensional stability even after multiple high-temperature cooling cycles, ensuring long-term accurate operation of the equipment.

Usage

Graphite protective sleeves are often used to cover temperature probes, thermocouples or other precision instruments to form a strong protective barrier. During installation, the protective cover must be in close contact with the device to avoid looseness or gaps that may reduce the protective effect. Additionally, regular inspection and cleaning of your protective cover can extend its lifespan and keep your device efficient.

Product advantages

- Cost-effective choice: Compared with other high-temperature materials, graphite protective sleeves have significant cost advantages. It not only provides excellent protection, but also meets the needs of efficient production at an affordable price.

- Wide applicability: Whether in metal smelting, glass manufacturing, or chemical reactors, graphite protective sleeves show excellent protective effects and strong adaptability.

- Environmentally friendly and pollution-free: Graphite is an environmentally friendly material and does not contain harmful substances. Its use will not produce by-products that are harmful to the environment and meet the environmental protection requirements of modern industry.

To sum up, graphite protective sleeves have become an ideal protection choice for various industrial equipment due to their outstanding high temperature resistance, oxidation resistance, corrosion resistance and other characteristics. In harsh operating environments, it not only provides strong protection for precision equipment, but also extends equipment life and reduces maintenance costs. Choose a graphite case from ABC Foundry Supplies Company to ensure high-quality, reliable protection for your device.