OEM Manufacturer Silicon Graphite Crucible

Features

We always get the job done being a tangible team to make certain that we can easily give you the very best high quality and the most effective rate for OEM Manufacturer Easy Handling Isostatically Pressed Silicon Carbide Crucibles for Metallurgical Analyses, Welcome all clients of dwelling and abroad to go to our corporation, to forge a fantastic long term by our cooperation.

We always get the job done being a tangible team to make certain that we can easily give you the very best high quality and the most effective rate for Silicon Graphite Crucible, Selling our solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

(1) High thermal conductivity: due to the use of raw materials such as graphite with high thermal conductivity, the melting time is shortened;

(2) Heat resistance and shock resistance: Strong heat resistance and shock resistance, resistant to cracking during rapid cooling and heating;

(3) High heat resistance: High temperature resistance, capable of withstanding high temperatures ranging from 1200 to 1650 ℃;

(4) Resistance to erosion: Strong resistance to erosion of molten soup;

(5) Resistance to mechanical impact: having a certain degree of strength against mechanical impact (such as the input of molten materials)

(6) Oxidation resistance: Graphite is prone to oxidation at high temperatures in oxidation aerosols, resulting in less oxidation consumption due to oxidation prevention treatment;

(7) Anti adhesion: Because graphite has the characteristic of not easily adhering to molten soup, the immersion and adhesion of molten soup are less;

(8) There is very little metal pollution: because there is no impurity mixed with the contaminated molten soup, there is very little metal pollution (mainly because iron is not added to the molten soup);

(9) Impact of slag collector (slag remover): It has good resistance to the impact of slag collector (slag remover) on performance.

Our Silicon carbide crucibles are used in a variety of industrial applications, like metallurgy, semiconductor manufacturing,glass production, and the chemical industry. Our Silicon carbide crucibles have the advantage of high-temperature melting and resistance to chemical attack. They are known for their excellent thermal conductivity,high thermal shock resistance, and resistance to chemical attack.

Standard parameter Test data

Temperature resistance ≥ 1630 ℃ Temperature resistance ≥ 1635 ℃

Carbon content ≥ 38% Carbon content ≥ 41.46%

Apparent porosity ≤ 35% Apparent porosity ≤ 32%

Volume density ≥ 1.6g/cm3 Volume density ≥ 1.71g/cm3

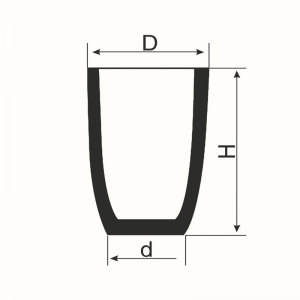

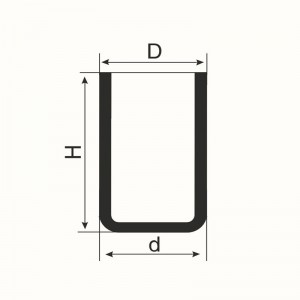

|

Item |

Code |

Height |

Outer Diameter |

Bottom Diameter |

|

RA100 |

100# |

380 |

330 |

205 |

|

RA200H400 |

180# |

400 |

400 |

230 |

|

RA200 |

200# |

450 |

410 |

230 |

|

RA300 |

300# |

450 |

450 |

230 |

|

RA350 |

349# |

590 |

460 |

230 |

|

RA350H510 |

345# |

510 |

460 |

230 |

|

RA400 |

400# |

600 |

530 |

310 |

|

RA500 |

500# |

660 |

530 |

310 |

|

RA600 |

501# |

700 |

530 |

310 |

|

RA800 |

650# |

800 |

570 |

330 |

|

RR351 |

351# |

650 |

420 |

230 |

1.Do you accept customized production based our specification?

Yes, Customized production based on your specifications available through our OEM and ODM service. Send us your drawing or idea, and we will work out the drawing for you.

2.What’s the delivery time?

Delivery time is 7 working days for standard products and 30 days for customized products.

3.What is the MOQ?

No limit to the quantity. We can offer the best proposal and solutions according to your condition.

4.How to deal with the faulty?

We produced in strict quality control systems, with a defective rate of less than 2%. If there are any problems with the product, we will provide free replacement.

Do you need reliable and durable crucibles for your high-temperature melting process? Silicon carbide graphite crucible is your best choice. This innovative refractory material is designed to withstand extreme temperatures and offers superior chemical stability, making it ideal for a variety of industrial applications.

Silicon carbide graphite crucibles are made from a unique mixture of ultra-fine silicon carbide particles and special graphite particles, and are sintered under high-pressure vacuum conditions to ensure their high performance and durability. Let’s dig into the key features that make this crucible stand out.

Unparalleled high temperature durability

One of the most impressive properties of silicon carbide graphite crucibles is their exceptional high temperature durability. The crucible can operate at temperatures exceeding 2500°C and can easily withstand the heat of various high-temperature environments. Whether you are involved in steelmaking, ironmaking or other high temperature smelting processes, this crucible is designed to meet and exceed your expectations.

Excellent chemical stability

In addition to their impressive heat resistance, silicon carbide graphite crucibles also offer excellent chemical stability. It has strong resistance to chemical reactions such as oxidation, ensuring that it is not affected by harmful gases and substances during use. This level of chemical stability not only protects the crucible itself, but also effectively protects the molten iron and alloy components from potential chemical attack, providing a reliable, safe environment for your smelting operations.

Wide range of applications

The versatility of silicon carbide graphite crucibles makes them a valuable asset in various industries. Whether you work in a foundry, metallurgical plant, or other high-temperature manufacturing facility, this crucible is ideal for a variety of applications, including melting, casting, and refining processes. Its adaptability and reliability make it an indispensable tool for professionals looking for consistent and high-quality results.

Long life and cost-effective

Investing in silicon carbide graphite crucibles means investing in long-term durability and cost-effectiveness. Its robust construction and wear resistance ensure a longer service life compared to traditional crucibles, ultimately reducing the need for frequent replacement and maintenance. This longevity translates to cost savings and increased operational efficiencies, making it a smart choice for businesses looking to optimize their smelting processes.

Environmentally friendly

Silicon carbide graphite crucibles are designed with environmental considerations in mind. Its chemical stability and resistance to harmful emissions make it an environmentally friendly choice for industrial applications. By minimizing the release of contaminants and maintaining a clean and safe working environment, the crucible meets sustainable practices and regulatory standards.

In conclusion, silicon carbide graphite crucibles are a game changer in high temperature smelting. Its exceptional high temperature durability, chemical stability, versatility, longevity and environmental friendliness make it the ultimate solution for professionals looking for reliable, efficient crucibles for their industrial processes.

Whether you are involved in steelmaking, ironmaking, or other high-temperature applications, silicon carbide graphite crucibles are your first choice for consistent, high-quality results. Make a smart investment in your smelting operation and experience the difference this innovative crucible can make.