Crucible for Melting Copper for Pouring Machine

Applications:

The Crucible for Copper Melting is widely used in various melting scenarios, including:

Casting Industry: Melting copper and copper alloys for the production of various castings and components.

Metallurgical Industry: High-temperature melting and refining in the purification and recycling processes of copper.

Laboratory Research: Small crucibles suitable for laboratory heat treatment and material research of copper.

1.To ensure product quality, we have designed a specialized production procedure that considers the acute thermal quenching conditions of the graphite crucible.

2.The even and fine basic design of the graphite crucible will significantly delay its erosion.

3The high thermal impact resistance of the graphite crucible allows it to withstand any process.

4.The high content of fixed carbon in the crucible allows for good heat conduction, shorter dissolution time, and reduced energy consumption.

5.The strict control of material components ensures that the graphite crucible will not pollute metals during the dissolving process.

6.Our quality guarantee system, combined with the process technology of forming under high pressure, ensures stable quality.

7.The graphite crucible has a small thermal expansion coefficient, high resistance to hot and cold strain, and strong corrosion resistance to acid and alkali solutions, making it ideal for high-temperature processes.

2. Install the pouring nozzle on the crucible opening.

3. Add a temperature measurement hole.

4. Make holes in the bottom or side according to the provided drawing

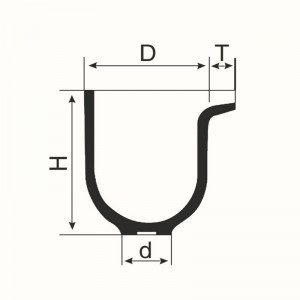

|

Item |

Code |

Height |

Outer Diameter |

Bottom Diameter |

|

CTN512 |

T1600# |

750 |

770 |

330 |

|

CTN587 |

T1800# |

900 |

800 |

330 |

|

CTN800 |

T3000# |

1000 |

880 |

350 |

|

CTN1100 |

T3300# |

1000 |

1170 |

530 |

|

CC510X530 |

C180# |

510 |

530 |

350 |

1.Store crucibles in a dry and cool place to prevent moisture absorption and corrosion.

2.Keep crucibles away from direct sunlight and heat sources to prevent deformation or cracking due to thermal expansion.

3.Store crucibles in a clean and dust-free environment to prevent contamination of the interior.

4.If possible, keep crucibles covered with a lid or wrapping to prevent dust, debris, or other foreign matter from entering.

5.Avoid stacking or piling crucibles on top of each other, as this can cause damage to the lower ones.

6.If you need to transport or move crucibles, handle them with care and avoid dropping or hitting them against hard surfaces.

7.Periodically inspect the crucibles for any signs of damage or wear, and replace them as needed.

How can we guarantee quality?

We guarantee quality through our process of always creating a pre-production sample before mass production and conducting a final inspection before shipment.

Why should you buy from us not from other suppliers?

Choosing us as your supplier means having access to our specialized equipment and receiving professional technical consultation and excellent after-sales service.

What value added services does your company provide?

In addition to custom production of graphite products, we also offer value-added services such as anti-oxidation impregnation and coating treatment, which can help to extend the service life of our products.